JEC World 2025: Continuous carbon fiber CF/PEEK

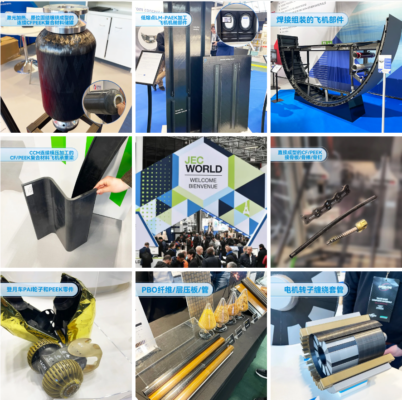

On March 6, JEC World 2025 was successfully concluded in Paris, France. As a major participant in China’s PEEK industry, Junhua Co., Ltd. demonstrated its innovative achievements and application solutions in the field of CF/PEEK, attracting the attention of many international customers and promoting in-depth exchanges and cooperation with upstream and downstream partners and professional audiences. Industry Trends | Thermoplastic Composites Open a New Era of “Lightweight” At the exhibition, the trend of thermoplastic composites replacing traditional thermosetting materials became more and more obvious. Compared with traditional epoxy materials, thermoplastic composites such as PEEK, PPS, PEI and other high-performance resin-based materials have the advantages of recyclability, high processing efficiency, strong impact resistance, high and low temperature resistance, corrosion resistance, etc., especially in aerospace, military industry, medical treatment, oil production and petrochemical industries. It has been widely used. Although its application in civilian markets such as home appliances, automobiles, and sports equipment has yet to be expanded, its lightweight and high-performance characteristics indicate a broad market prospect.  Technological breakthrough | LM-PAEK materials lead the innovation trend The low-melting-point LM-PAEK materials launched by foreign friends and downstream users have become the focus of the exhibition. Junhua shares have insight into customer needs and keep up with the international industry technology trends. It has completed the small and medium tests of the material and provided customers with small batches of product trials. It plans to focus on promoting domestic LM-PAEK particles in the next exhibition. Many domestic customers have expressed their intention to cooperate. In addition, a long fiber reinforced bone plate exhibited by a German medical device company uses direct molding technology, which provides innovative process ideas for the medical field and deserves continued attention from domestic peers. Frontier Intelligent Manufacturing | Innovation in Thermoplastic Composite Welding and Forming Technology Thermoplastic Composite Welding Equipment: KVE INDUCT® exhibited thermoplastic composite induction welding equipment and processes, which generate heat by inducing eddy currents in carbon fiber reinforced laminates to melt the polymer and form a strong connection. Welding is performed in a rigid mold, and the composite laminate is fixed in a specified position. The welding coil moves over the component to melt the polymer at the desired location. The temperature of the welding area is controlled by a proprietary radiator. This technology is capable of welding closed box structures of different thicknesses and curvatures, and there is basically no limit on the size of the component. Compared with thermosetting composites, this technology can reduce costs by 20% and reduce weight by 10%. It can be widely used in products such as aircraft doors, beam panels, etc.

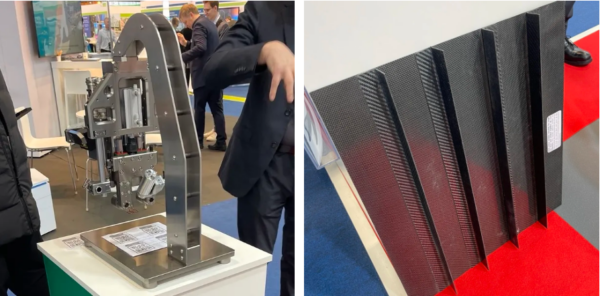

Technological breakthrough | LM-PAEK materials lead the innovation trend The low-melting-point LM-PAEK materials launched by foreign friends and downstream users have become the focus of the exhibition. Junhua shares have insight into customer needs and keep up with the international industry technology trends. It has completed the small and medium tests of the material and provided customers with small batches of product trials. It plans to focus on promoting domestic LM-PAEK particles in the next exhibition. Many domestic customers have expressed their intention to cooperate. In addition, a long fiber reinforced bone plate exhibited by a German medical device company uses direct molding technology, which provides innovative process ideas for the medical field and deserves continued attention from domestic peers. Frontier Intelligent Manufacturing | Innovation in Thermoplastic Composite Welding and Forming Technology Thermoplastic Composite Welding Equipment: KVE INDUCT® exhibited thermoplastic composite induction welding equipment and processes, which generate heat by inducing eddy currents in carbon fiber reinforced laminates to melt the polymer and form a strong connection. Welding is performed in a rigid mold, and the composite laminate is fixed in a specified position. The welding coil moves over the component to melt the polymer at the desired location. The temperature of the welding area is controlled by a proprietary radiator. This technology is capable of welding closed box structures of different thicknesses and curvatures, and there is basically no limit on the size of the component. Compared with thermosetting composites, this technology can reduce costs by 20% and reduce weight by 10%. It can be widely used in products such as aircraft doors, beam panels, etc.  PINETTE PEI continuous stamping equipment: Using a hydraulic press integrated with an infrared oven system and a robotic arm, the material blank can be transferred from the loading station to the infrared oven, back to the forming mold and back to the loading station for the next cycle. The cyclic operation and rapid temperature rise and fall can achieve continuous and efficient stamping and compression molding of thermoplastic composite products, greatly improving efficiency and reducing costs.

PINETTE PEI continuous stamping equipment: Using a hydraulic press integrated with an infrared oven system and a robotic arm, the material blank can be transferred from the loading station to the infrared oven, back to the forming mold and back to the loading station for the next cycle. The cyclic operation and rapid temperature rise and fall can achieve continuous and efficient stamping and compression molding of thermoplastic composite products, greatly improving efficiency and reducing costs.  AFPT thermoplastic composite winding and wire laying equipment: The thermoplastic prepreg tape is wound and laid according to a preset shape or procedure, and laser radiation is used as a heat source for welding. It can achieve very precise temperature control, thereby achieving extremely high welding quality in in-situ curing, and realizing high-cost-effective production of large quantities of thermoplastic composite parts, such as magnetic pump isolation sleeves, high-pressure hydrogen tanks, new energy vehicle motor rotors, missile tanks, etc.

AFPT thermoplastic composite winding and wire laying equipment: The thermoplastic prepreg tape is wound and laid according to a preset shape or procedure, and laser radiation is used as a heat source for welding. It can achieve very precise temperature control, thereby achieving extremely high welding quality in in-situ curing, and realizing high-cost-effective production of large quantities of thermoplastic composite parts, such as magnetic pump isolation sleeves, high-pressure hydrogen tanks, new energy vehicle motor rotors, missile tanks, etc.  Market Opportunities | ChinaPEEK’s Global Competitiveness In the wave of international market competition, European leading companies are facing increasing cost pressure, which provides valuable opportunities for domestic PEEK materials to go overseas. With its wide range of applications and rich success stories, the market scale of PEEK materials continues to expand, and market demand also shows a strong growth trend. Chinese PEEK polymerization, modified granulation and profile continuous extrusion companies have sprung up like mushrooms after a rain. Not only has the number increased sharply, but also increased investment in innovative research and development and after-sales technical services, which has significantly improved product quality and further enhanced international competitiveness. As one of the best, Junhua shares, its foreign trade team actively connects with the needs of the international market, and is committed to promoting high-quality domestic PEEK materials to the global stage.

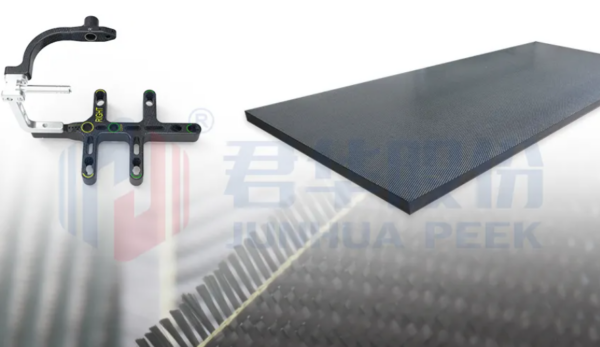

Market Opportunities | ChinaPEEK’s Global Competitiveness In the wave of international market competition, European leading companies are facing increasing cost pressure, which provides valuable opportunities for domestic PEEK materials to go overseas. With its wide range of applications and rich success stories, the market scale of PEEK materials continues to expand, and market demand also shows a strong growth trend. Chinese PEEK polymerization, modified granulation and profile continuous extrusion companies have sprung up like mushrooms after a rain. Not only has the number increased sharply, but also increased investment in innovative research and development and after-sales technical services, which has significantly improved product quality and further enhanced international competitiveness. As one of the best, Junhua shares, its foreign trade team actively connects with the needs of the international market, and is committed to promoting high-quality domestic PEEK materials to the global stage.  In order to further expand the European market, Junhua shares established JUNDE HPP subsidiary in Düsseldorf, North Rhine-Westphalia, Germany (the venue of the K show), and equipped it with exhibition halls and offices to actively expand the European market. At the same time, facing the technical barriers of high-end composite equipment (such as winding machines, wire laying machines, etc.), Junhua shares is accelerating its layout in the field of prepreg tape equipment through flexible modular procurement strategies and in-depth localized research and development, in order to seize the technical commanding heights and lay a solid foundation for the company’s long-term development. Strategic Focus | Deeply cultivate high value-added tracks In the future, Junhua will deepen cooperative development with downstream customers, jointly promote CF/PEEK composite materials, and establish technical barriers in high-end fields such as aerospace and implant-grade medical. At the same time, Junhua will increase its R&D investment in high-value-added products such as carbon fiber reinforced PEEK (CF/PEEK) and implant-grade AKSOPEEK on the basis of mass production of pure PEEK materials, and promote the transformation of enterprises to “specialization, precision and innovation”.

In order to further expand the European market, Junhua shares established JUNDE HPP subsidiary in Düsseldorf, North Rhine-Westphalia, Germany (the venue of the K show), and equipped it with exhibition halls and offices to actively expand the European market. At the same time, facing the technical barriers of high-end composite equipment (such as winding machines, wire laying machines, etc.), Junhua shares is accelerating its layout in the field of prepreg tape equipment through flexible modular procurement strategies and in-depth localized research and development, in order to seize the technical commanding heights and lay a solid foundation for the company’s long-term development. Strategic Focus | Deeply cultivate high value-added tracks In the future, Junhua will deepen cooperative development with downstream customers, jointly promote CF/PEEK composite materials, and establish technical barriers in high-end fields such as aerospace and implant-grade medical. At the same time, Junhua will increase its R&D investment in high-value-added products such as carbon fiber reinforced PEEK (CF/PEEK) and implant-grade AKSOPEEK on the basis of mass production of pure PEEK materials, and promote the transformation of enterprises to “specialization, precision and innovation”.  In this exhibition, many Chinese companies were absent due to lack of continuous investment, which once again proved that the composite materials industry needs to be deeply cultivated and persisted. The composite material subsidiary of Junhua Group is optimizing its strategic planning, striving to stand out in the market and set an industry benchmark through precise positioning and technological iteration. Junhua Group’s participation in the exhibition not only demonstrated its innovative strength in the CF/PEEK field, but also injected new vitality into the future development of high-performance thermoplastic composite materials such as PEEK, PEK, and PPS.

In this exhibition, many Chinese companies were absent due to lack of continuous investment, which once again proved that the composite materials industry needs to be deeply cultivated and persisted. The composite material subsidiary of Junhua Group is optimizing its strategic planning, striving to stand out in the market and set an industry benchmark through precise positioning and technological iteration. Junhua Group’s participation in the exhibition not only demonstrated its innovative strength in the CF/PEEK field, but also injected new vitality into the future development of high-performance thermoplastic composite materials such as PEEK, PEK, and PPS.