Continuous carbon fiber CF/PEEK thermoplastic composites

Continuous fiber composites, based on their unique fiber arrangement and thermoplastic process, are gradually becoming the leader in the field of lightweight materials. This composite material not only has excellent mechanical properties, but also has been widely used in aerospace, wind power, automobile manufacturing, and high-end equipment manufacturing due to its lightweight characteristics. In terms of the selection of matrix materials, continuous fiber composites mainly rely on traditional thermosetting matrices and emerging thermoplastic matrices. Thermosetting composites play an important role in many fields with their stable cross-linked structure and good mechanical properties. However, the irreversibility of its molding process and its dependence on low-temperature storage environment limit its further development in some high-end application fields.  In contrast, thermoplastic composites stand out with their greater flexibility and reusability. Composite materials based on high-performance thermoplastic resins (such as PEEK, PEI, PPS, etc.) not only have excellent mechanical properties, chemical corrosion resistance and high temperature resistance, but can also be repeatedly shaped through processes such as heating, melting and plasticizing, cooling and solidification. This feature not only improves the utilization rate of materials, but also significantly reduces production costs, making thermoplastic composite materials popular in aerospace, medical devices, automobile manufacturing, drones and other fields.

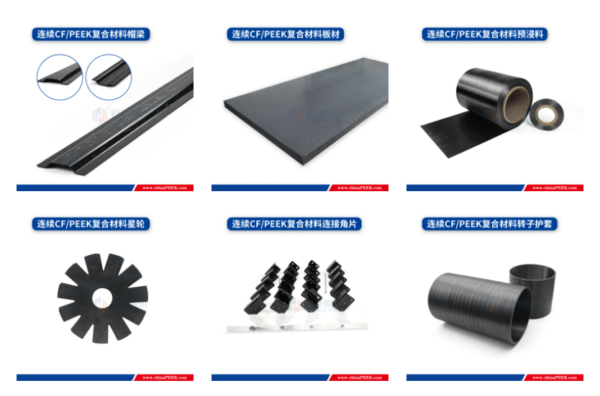

In contrast, thermoplastic composites stand out with their greater flexibility and reusability. Composite materials based on high-performance thermoplastic resins (such as PEEK, PEI, PPS, etc.) not only have excellent mechanical properties, chemical corrosion resistance and high temperature resistance, but can also be repeatedly shaped through processes such as heating, melting and plasticizing, cooling and solidification. This feature not only improves the utilization rate of materials, but also significantly reduces production costs, making thermoplastic composite materials popular in aerospace, medical devices, automobile manufacturing, drones and other fields.  As a leading company in the field of thermoplastic composite materials, the company has developed a series of high-performance thermoplastic composite materials products. These products include CF/PEEK, CF/PEI, CF/PPS, etc., which are widely used in aerospace, medical devices and other fields. It not only meets the high requirements for material performance in these fields, but also improves the reliability and safety of products through innovative product forms, such as thermoplastic composite prepregs and sheets, felt fiber reinforced thermoplastic composite sheets, CF/PEEK corner pieces for aerospace, implant-grade CF/PEEK bone plates, continuous CF/PEEK surgical stents and sights, high wear-resistant CF/PEEK composite star wheels, motor rotor sleeves, magnetic pump isolation sleeves, etc. In terms of intellectual property rights, it has also achieved remarkable results. The company has obtained 7 invention patent authorizations and has won many important awards at home and abroad. Among them, Junhua’s “continuous carbon fiber reinforced PEEK thermoplastic composite” products have also passed the appraisal organized by the Jiangsu Provincial Department of Industry and Information Technology and have been recognized as “internationally advanced” level. Looking to the future, Junhua will continue to deepen its thermoplastic composite field and devote itself to research and development and innovation.

As a leading company in the field of thermoplastic composite materials, the company has developed a series of high-performance thermoplastic composite materials products. These products include CF/PEEK, CF/PEI, CF/PPS, etc., which are widely used in aerospace, medical devices and other fields. It not only meets the high requirements for material performance in these fields, but also improves the reliability and safety of products through innovative product forms, such as thermoplastic composite prepregs and sheets, felt fiber reinforced thermoplastic composite sheets, CF/PEEK corner pieces for aerospace, implant-grade CF/PEEK bone plates, continuous CF/PEEK surgical stents and sights, high wear-resistant CF/PEEK composite star wheels, motor rotor sleeves, magnetic pump isolation sleeves, etc. In terms of intellectual property rights, it has also achieved remarkable results. The company has obtained 7 invention patent authorizations and has won many important awards at home and abroad. Among them, Junhua’s “continuous carbon fiber reinforced PEEK thermoplastic composite” products have also passed the appraisal organized by the Jiangsu Provincial Department of Industry and Information Technology and have been recognized as “internationally advanced” level. Looking to the future, Junhua will continue to deepen its thermoplastic composite field and devote itself to research and development and innovation.