PEEK amplitude modulation nut: an innovative alternative to traditional copper nuts

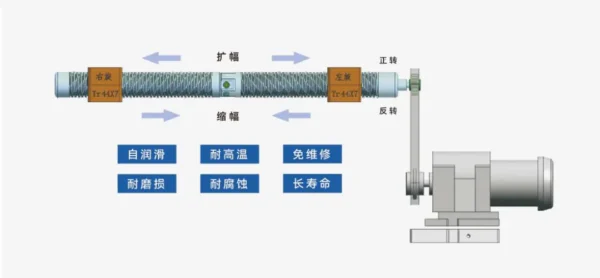

In the process of stenting and shaping of textile printing and dyeing enterprises, the strut nuts on the stenter and shaping machines play a key role in adjusting the position of the fabric guide rails and adapting to various widths. When facing a working environment of up to 220°C, traditional copper alloy strut nuts often tightly bite with the metal wire rod due to high temperature, causing downtime. Although relying on external lubricants such as molybdenum disulfide can alleviate this problem, it is easy to pollute the fabric and affect product quality.

PEEK, with its excellent high temperature resistance (long-term use temperature up to 260°C) and natural self-lubricating properties, perfectly solves the problem of nuts and wire rods biting at high temperatures, while avoiding the potential contamination of lubricants to fabrics, achieving a double leap in efficiency and clean production. In actual use, the service life of PEEK strut nuts is significantly improved by three times compared with traditional copper alloy products, greatly reducing maintenance costs and improving production efficiency.

With the advantage of self-produced PEEK raw materials, through cost control and process optimization, the production efficiency and delivery speed of the modulating nuts have been greatly improved, and the price has been reduced by 33% compared with the original, which can provide customers with more cost-effective PEEK products. The modulating nuts made of the existing PEEK5600CF30 and PEEK5600GF30 grades are respectively added with carbon fiber and glass fiber to enhance their strength and wear resistance, which are suitable for different application scenarios and meet the diverse needs of different customers.