Application of PEEK in radar antenna cover

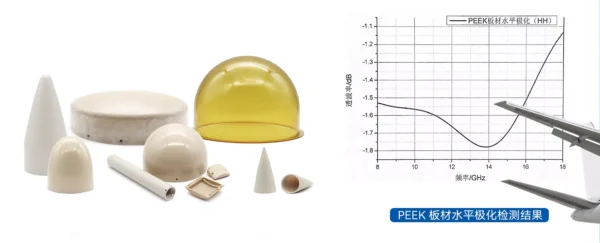

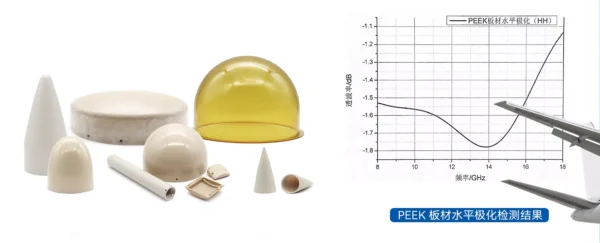

PEEK radomePEEK radome has outstanding weather resistance, high strength, wave transparency and corrosion resistance. Compared with other radome materials, its electrical performance is more stable in extreme temperature environments.  Jiangsu Junhua Co., Ltd.: Aircraft Internal and External Applications Aerospace engineers need a variety of lightweight materials that can be flexibly processed, reduce manufacturing costs, and withstand harsh environments. In more and more aviation applications, PEEK polymer materials are used because of their exceptional strength, chemical inertness, flame retardancy, and easy processing into parts with extremely small tolerances. Lighter flying and more fuel efficient ▲ Up to 70% weight reduction compared to metal, while having the same strength and stiffness; Efficient production ▲ Production by injection molding allows engineers to simplify and standardize parts, and can combine multiple parts into a functional component; ▲ Fewer parts and easier installation, which speeds up assembly and reduces system costs. Reliable quality ▲ Under 260℃ (500℉), no stress heating aging for more than 5000 hours, no loss of tensile strength performance; ▲ Dimensionally stable and has excellent creep resistance, fatigue resistance and moisture resistance; ▲ Tolerance to aviation fuel, hydraulic oil, deicing solution, pesticides, cleaning fluids, fire extinguishing chemicals, water, salt and steam; ▲ Fire rating is UL94 V-0, with low smoke and low toxic gas emissions. It has successfully replaced metal, traditional composite materials and other plastics. PEEK cable ties Used to bundle cables and fix them to the fuselage. The low moisture absorption of PEEK polymer ensures that the wire binding is dimensionally stable and does not expand and damage the wire insulation. PEEK composite fasteners Aircraft structures using lightweight composite materials are becoming the standard for new aircraft development. Made into true lightweight restraint systems, bolts and nuts, plugs and brackets. Has the advantages of fatigue resistance, high strength and corrosion resistance. PEEK radar antenna cover PEEK polymer material can be made into high-dimensional precision radar antenna cover by injection molding, which has the following advantages: ▲Excellent rainproof performance ▲High strength ▲More stable electrical performance in extreme temperature environments compared to other radar antenna cover materials. PEEK parts for aerospace PEEK features and advantages: ◆ High temperature resistance ◆ Wear resistance ◆ Self-lubrication ◆ Corrosion resistance ◆ High strength ◆ Easy processing ◆ Hydrolysis resistance ◆ Flame retardant ◆ Low smoke and non-toxic ◆ Electrical properties ◆ Radiation resistance ◆ Dimensional stability

Jiangsu Junhua Co., Ltd.: Aircraft Internal and External Applications Aerospace engineers need a variety of lightweight materials that can be flexibly processed, reduce manufacturing costs, and withstand harsh environments. In more and more aviation applications, PEEK polymer materials are used because of their exceptional strength, chemical inertness, flame retardancy, and easy processing into parts with extremely small tolerances. Lighter flying and more fuel efficient ▲ Up to 70% weight reduction compared to metal, while having the same strength and stiffness; Efficient production ▲ Production by injection molding allows engineers to simplify and standardize parts, and can combine multiple parts into a functional component; ▲ Fewer parts and easier installation, which speeds up assembly and reduces system costs. Reliable quality ▲ Under 260℃ (500℉), no stress heating aging for more than 5000 hours, no loss of tensile strength performance; ▲ Dimensionally stable and has excellent creep resistance, fatigue resistance and moisture resistance; ▲ Tolerance to aviation fuel, hydraulic oil, deicing solution, pesticides, cleaning fluids, fire extinguishing chemicals, water, salt and steam; ▲ Fire rating is UL94 V-0, with low smoke and low toxic gas emissions. It has successfully replaced metal, traditional composite materials and other plastics. PEEK cable ties Used to bundle cables and fix them to the fuselage. The low moisture absorption of PEEK polymer ensures that the wire binding is dimensionally stable and does not expand and damage the wire insulation. PEEK composite fasteners Aircraft structures using lightweight composite materials are becoming the standard for new aircraft development. Made into true lightweight restraint systems, bolts and nuts, plugs and brackets. Has the advantages of fatigue resistance, high strength and corrosion resistance. PEEK radar antenna cover PEEK polymer material can be made into high-dimensional precision radar antenna cover by injection molding, which has the following advantages: ▲Excellent rainproof performance ▲High strength ▲More stable electrical performance in extreme temperature environments compared to other radar antenna cover materials. PEEK parts for aerospace PEEK features and advantages: ◆ High temperature resistance ◆ Wear resistance ◆ Self-lubrication ◆ Corrosion resistance ◆ High strength ◆ Easy processing ◆ Hydrolysis resistance ◆ Flame retardant ◆ Low smoke and non-toxic ◆ Electrical properties ◆ Radiation resistance ◆ Dimensional stability

Jiangsu Junhua Co., Ltd.: Aircraft Internal and External Applications Aerospace engineers need a variety of lightweight materials that can be flexibly processed, reduce manufacturing costs, and withstand harsh environments. In more and more aviation applications, PEEK polymer materials are used because of their exceptional strength, chemical inertness, flame retardancy, and easy processing into parts with extremely small tolerances. Lighter flying and more fuel efficient ▲ Up to 70% weight reduction compared to metal, while having the same strength and stiffness; Efficient production ▲ Production by injection molding allows engineers to simplify and standardize parts, and can combine multiple parts into a functional component; ▲ Fewer parts and easier installation, which speeds up assembly and reduces system costs. Reliable quality ▲ Under 260℃ (500℉), no stress heating aging for more than 5000 hours, no loss of tensile strength performance; ▲ Dimensionally stable and has excellent creep resistance, fatigue resistance and moisture resistance; ▲ Tolerance to aviation fuel, hydraulic oil, deicing solution, pesticides, cleaning fluids, fire extinguishing chemicals, water, salt and steam; ▲ Fire rating is UL94 V-0, with low smoke and low toxic gas emissions. It has successfully replaced metal, traditional composite materials and other plastics. PEEK cable ties Used to bundle cables and fix them to the fuselage. The low moisture absorption of PEEK polymer ensures that the wire binding is dimensionally stable and does not expand and damage the wire insulation. PEEK composite fasteners Aircraft structures using lightweight composite materials are becoming the standard for new aircraft development. Made into true lightweight restraint systems, bolts and nuts, plugs and brackets. Has the advantages of fatigue resistance, high strength and corrosion resistance. PEEK radar antenna cover PEEK polymer material can be made into high-dimensional precision radar antenna cover by injection molding, which has the following advantages: ▲Excellent rainproof performance ▲High strength ▲More stable electrical performance in extreme temperature environments compared to other radar antenna cover materials. PEEK parts for aerospace PEEK features and advantages: ◆ High temperature resistance ◆ Wear resistance ◆ Self-lubrication ◆ Corrosion resistance ◆ High strength ◆ Easy processing ◆ Hydrolysis resistance ◆ Flame retardant ◆ Low smoke and non-toxic ◆ Electrical properties ◆ Radiation resistance ◆ Dimensional stability

Jiangsu Junhua Co., Ltd.: Aircraft Internal and External Applications Aerospace engineers need a variety of lightweight materials that can be flexibly processed, reduce manufacturing costs, and withstand harsh environments. In more and more aviation applications, PEEK polymer materials are used because of their exceptional strength, chemical inertness, flame retardancy, and easy processing into parts with extremely small tolerances. Lighter flying and more fuel efficient ▲ Up to 70% weight reduction compared to metal, while having the same strength and stiffness; Efficient production ▲ Production by injection molding allows engineers to simplify and standardize parts, and can combine multiple parts into a functional component; ▲ Fewer parts and easier installation, which speeds up assembly and reduces system costs. Reliable quality ▲ Under 260℃ (500℉), no stress heating aging for more than 5000 hours, no loss of tensile strength performance; ▲ Dimensionally stable and has excellent creep resistance, fatigue resistance and moisture resistance; ▲ Tolerance to aviation fuel, hydraulic oil, deicing solution, pesticides, cleaning fluids, fire extinguishing chemicals, water, salt and steam; ▲ Fire rating is UL94 V-0, with low smoke and low toxic gas emissions. It has successfully replaced metal, traditional composite materials and other plastics. PEEK cable ties Used to bundle cables and fix them to the fuselage. The low moisture absorption of PEEK polymer ensures that the wire binding is dimensionally stable and does not expand and damage the wire insulation. PEEK composite fasteners Aircraft structures using lightweight composite materials are becoming the standard for new aircraft development. Made into true lightweight restraint systems, bolts and nuts, plugs and brackets. Has the advantages of fatigue resistance, high strength and corrosion resistance. PEEK radar antenna cover PEEK polymer material can be made into high-dimensional precision radar antenna cover by injection molding, which has the following advantages: ▲Excellent rainproof performance ▲High strength ▲More stable electrical performance in extreme temperature environments compared to other radar antenna cover materials. PEEK parts for aerospace PEEK features and advantages: ◆ High temperature resistance ◆ Wear resistance ◆ Self-lubrication ◆ Corrosion resistance ◆ High strength ◆ Easy processing ◆ Hydrolysis resistance ◆ Flame retardant ◆ Low smoke and non-toxic ◆ Electrical properties ◆ Radiation resistance ◆ Dimensional stability