PEEK5600FG25 | A new material for flat wire motors

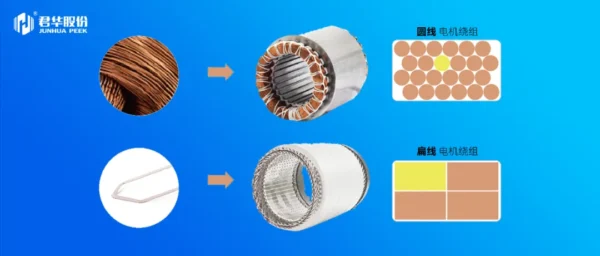

With the rapid development of new energy vehicle technology, high-voltage platforms above 800V have become the mainstream choice for drive motors, providing vehicles with fast and efficient charging capabilities and excellent driving experience. However, traditional thermosetting PI (polyimide) materials are prone to stress concentration during bending or winding, leading to the risk of cracking, posing a serious threat to the safety of the entire vehicle. Against this background, flat wire motors came into being, and PEEK quickly became the preferred material for drive motors with its unique advantages. PEEK flat wire has high slot fill rate, compact structure, excellent toughness, bending resistance, excellent electrical properties and solvent resistance, which enable it to easily cope with various challenges in high-voltage environments.  As an innovative material for flat wire motor technology, PEEK has become the key to improving the insulation performance and power density of motors with its excellent high temperature resistance, wear resistance, corona corrosion resistance and fatigue resistance. In the 800V high-voltage fast charging environment, PEEK flat wire not only easily copes with high voltage and high PDIV (partial discharge initiation voltage) requirements, but also maximizes the wire density through single-layer extrusion technology, further promoting the improvement of drive motor performance. The advantages of PEEK materials are not limited to electrical performance, but its performance in heat dissipation is also impressive. The rectangular cross-section design of PEEK flat wire optimizes the internal gap and increases the contact area between conductors, thereby significantly improving the heat conduction efficiency. Combined with oil injection cooling technology, the winding temperature of the PEEK flat wire motor can be greatly reduced, ensuring the stable operation of the motor under extreme working conditions.

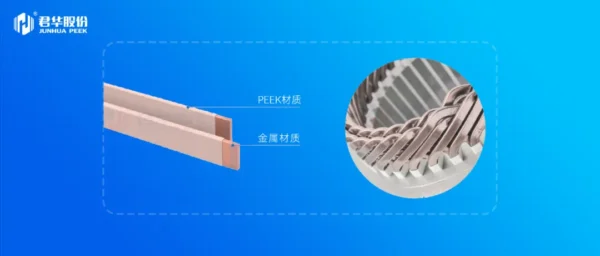

As an innovative material for flat wire motor technology, PEEK has become the key to improving the insulation performance and power density of motors with its excellent high temperature resistance, wear resistance, corona corrosion resistance and fatigue resistance. In the 800V high-voltage fast charging environment, PEEK flat wire not only easily copes with high voltage and high PDIV (partial discharge initiation voltage) requirements, but also maximizes the wire density through single-layer extrusion technology, further promoting the improvement of drive motor performance. The advantages of PEEK materials are not limited to electrical performance, but its performance in heat dissipation is also impressive. The rectangular cross-section design of PEEK flat wire optimizes the internal gap and increases the contact area between conductors, thereby significantly improving the heat conduction efficiency. Combined with oil injection cooling technology, the winding temperature of the PEEK flat wire motor can be greatly reduced, ensuring the stable operation of the motor under extreme working conditions.

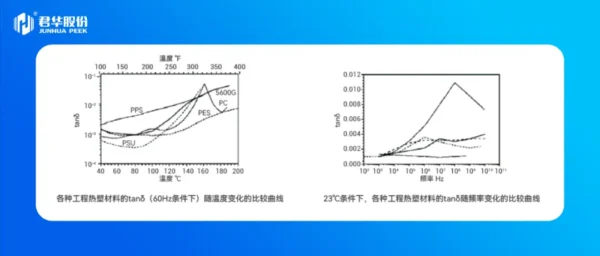

In addition, PEEK material also shows extraordinary strength in processing performance and environmental protection. Its good fluidity in the molten state and its mechanical properties and dimensional stability after solidification make PEEK flat wires able to be processed and formed in one go through the extrusion process, reducing the difficulty and cost of processing. At the same time, the non-toxic and pollution-free characteristics of PEEK materials, as well as the complete recyclability of waste materials during processing, not only conform to the concept of green production, but also further reduce production costs, achieving a win-win situation of economic and environmental benefits. In response to the specific needs of flat wire motors, Junhua independently developed PEEK5600FG25 particles, which are specially designed for flat wire motors. Compared with the PEEK material of ordinary cables, PEEK5600FG25 has better viscosity and can be more tightly combined with the wire. The specific significant characteristics are as follows: High-toughness PEEK5600FG25 has higher strength and better toughness. Its main molecular chain has both flexible groups-ether bonds and rigid groups-benzene rings, which enable the material to maintain structural integrity when subjected to mechanical stress or vibration, and is not easy to break or deform, providing a more solid safety guarantee for the entire new energy vehicle system. High temperature resistant PEEK flat wire has excellent high temperature resistance and can work continuously in high temperature environments up to 260°C, while the temperature resistance range of PI (polyimide) enameled wire is usually between 80-200°C, which makes PEEK flat wire have better stability and service life in high temperature environments. Low dielectric constant and dielectric loss factor The dielectric constant of PEEK5600FG25 is only 3.0, which is slightly higher than PE (polyethylene) and fluoroplastics, but much lower than PVC (polyvinyl chloride). The comparison curve in the figure below shows that within the frequency range of 109Hz, ordinary PEEK polymer has good electrical properties. Many electrical properties of this material meet the typical properties of thermoplastic materials. At the same time, PEEK polymer also maintains these excellent insulation properties over a very wide temperature and frequency range. As can be seen from the figure, the tanδ loss of PEEK material is small below 140°C.

In addition, PEEK material also shows extraordinary strength in processing performance and environmental protection. Its good fluidity in the molten state and its mechanical properties and dimensional stability after solidification make PEEK flat wires able to be processed and formed in one go through the extrusion process, reducing the difficulty and cost of processing. At the same time, the non-toxic and pollution-free characteristics of PEEK materials, as well as the complete recyclability of waste materials during processing, not only conform to the concept of green production, but also further reduce production costs, achieving a win-win situation of economic and environmental benefits. In response to the specific needs of flat wire motors, Junhua independently developed PEEK5600FG25 particles, which are specially designed for flat wire motors. Compared with the PEEK material of ordinary cables, PEEK5600FG25 has better viscosity and can be more tightly combined with the wire. The specific significant characteristics are as follows: High-toughness PEEK5600FG25 has higher strength and better toughness. Its main molecular chain has both flexible groups-ether bonds and rigid groups-benzene rings, which enable the material to maintain structural integrity when subjected to mechanical stress or vibration, and is not easy to break or deform, providing a more solid safety guarantee for the entire new energy vehicle system. High temperature resistant PEEK flat wire has excellent high temperature resistance and can work continuously in high temperature environments up to 260°C, while the temperature resistance range of PI (polyimide) enameled wire is usually between 80-200°C, which makes PEEK flat wire have better stability and service life in high temperature environments. Low dielectric constant and dielectric loss factor The dielectric constant of PEEK5600FG25 is only 3.0, which is slightly higher than PE (polyethylene) and fluoroplastics, but much lower than PVC (polyvinyl chloride). The comparison curve in the figure below shows that within the frequency range of 109Hz, ordinary PEEK polymer has good electrical properties. Many electrical properties of this material meet the typical properties of thermoplastic materials. At the same time, PEEK polymer also maintains these excellent insulation properties over a very wide temperature and frequency range. As can be seen from the figure, the tanδ loss of PEEK material is small below 140°C.  PEEK material has become an ideal choice for flat wire motor materials under the 800V high-voltage platform due to its excellent performance and wide application potential. With the continuous expansion of the electric vehicle market and the acceleration of technological iteration, PEEK material will play a more important role in promoting the improvement of electric vehicle charging speed and performance optimization, and contribute to the green development of the new energy vehicle industry.

PEEK material has become an ideal choice for flat wire motor materials under the 800V high-voltage platform due to its excellent performance and wide application potential. With the continuous expansion of the electric vehicle market and the acceleration of technological iteration, PEEK material will play a more important role in promoting the improvement of electric vehicle charging speed and performance optimization, and contribute to the green development of the new energy vehicle industry.