Breakthrough of the bottleneck of single screw mechanical transmission

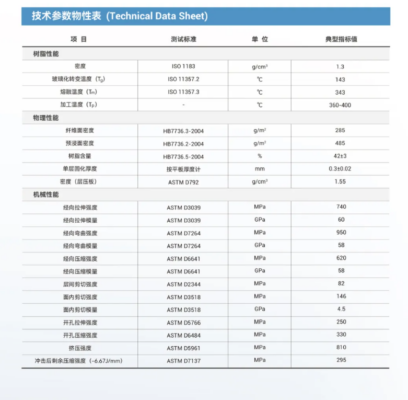

In the field of precision transmission of single-screw machinery, the performance of the star wheel is directly related to the life and operating efficiency of the equipment. Although PEEK raw materials have significant advantages such as high temperature resistance and corrosion resistance, problems such as fast wear and easy deformation under extreme working conditions still become bottlenecks restricting its application. Junhua Co., Ltd. has brought a breakthrough solution to the industry with its innovatively developed CF/PEEK star wheel. CF/PEEK star wheel has achieved a comprehensive upgrade of material performance through a special material ratio process. The carbon fiber content is as high as 40%-50%, and a small amount of PTFE (polytetrafluoroethylene) is added for modification, which significantly improves the mechanical strength, wear resistance and temperature resistance. The tensile strength is more than 7 times higher than that of ordinary PEEK, the creep resistance is significantly enhanced, and the meshing accuracy can still be maintained under long-term load. The friction coefficient is stable in the range of 0.15-0.25, and the wear rate is only 1/2 of that of ordinary PEEK. The continuous working temperature can reach 300℃, and the instantaneous temperature resistance is as high as 330℃, which perfectly adapts to more stringent working conditions.  In view of the special stress distribution of the single screw system, Junhua’s technical team optimized the structure of the star wheel through simulation and dynamic load testing. The optimized tooth profile and fiber arrangement direction effectively disperse the stress, reducing the local stress concentration by more than 25%. Under high-pressure alternating loads, the deformation of the CF/PEEK star wheel is 60% lower than that of ordinary PEEK, ensuring the stability of long-term operation. Actual measured data show that in a certain enterprise compressor application, the CF/PEEK star wheel still maintains 92% of the initial accuracy after 8,000 hours of continuous operation, far exceeding the average life of ordinary PEEK. As a benchmark enterprise in the field of special engineering plastics in China, CF/PEEK star wheel has three core advantages. First, it has patented CF/PEEK composite material molding technology (patent number: ZL201910443696.8), which ensures the uniform distribution of carbon fiber in the matrix and avoids performance fluctuations. Second, it has established a full-process quality control system, from raw material screening, material molding to finished product processing, real-time monitoring of 20+ key parameters, and batch consistency of up to 99.5%. Third, it provides customized service capabilities and can provide personalized material modification solutions based on customer equipment parameters.

In view of the special stress distribution of the single screw system, Junhua’s technical team optimized the structure of the star wheel through simulation and dynamic load testing. The optimized tooth profile and fiber arrangement direction effectively disperse the stress, reducing the local stress concentration by more than 25%. Under high-pressure alternating loads, the deformation of the CF/PEEK star wheel is 60% lower than that of ordinary PEEK, ensuring the stability of long-term operation. Actual measured data show that in a certain enterprise compressor application, the CF/PEEK star wheel still maintains 92% of the initial accuracy after 8,000 hours of continuous operation, far exceeding the average life of ordinary PEEK. As a benchmark enterprise in the field of special engineering plastics in China, CF/PEEK star wheel has three core advantages. First, it has patented CF/PEEK composite material molding technology (patent number: ZL201910443696.8), which ensures the uniform distribution of carbon fiber in the matrix and avoids performance fluctuations. Second, it has established a full-process quality control system, from raw material screening, material molding to finished product processing, real-time monitoring of 20+ key parameters, and batch consistency of up to 99.5%. Third, it provides customized service capabilities and can provide personalized material modification solutions based on customer equipment parameters.  Faced with the development trend of the single-screw compressor market with an annual growth rate of more than 5%, relying on the advantages of the entire industry chain integrating PEEK resin raw material polymerization, finished parts research and development, production and sales, it provides customers with a full range of service support. This includes providing 200 hours of free simulated working condition verification service, completing non-standard tooth profile parameter analysis within 48 hours, and providing 12,000 hours of operating quality assurance. These services not only improve customer satisfaction and trust, but also give Junhua a head start in market competition. The innovative research and development and application of CF/PEEK star wheel pieces not only solve the performance bottleneck problem of traditional PEEK materials under extreme working conditions, but also bring new solutions and development opportunities to the field of precision transmission of single-screw machinery. With the continuous growth of market demand and continuous technological innovation, Junhua will continue to lead the industry and provide more customers with high-quality products and services.

Faced with the development trend of the single-screw compressor market with an annual growth rate of more than 5%, relying on the advantages of the entire industry chain integrating PEEK resin raw material polymerization, finished parts research and development, production and sales, it provides customers with a full range of service support. This includes providing 200 hours of free simulated working condition verification service, completing non-standard tooth profile parameter analysis within 48 hours, and providing 12,000 hours of operating quality assurance. These services not only improve customer satisfaction and trust, but also give Junhua a head start in market competition. The innovative research and development and application of CF/PEEK star wheel pieces not only solve the performance bottleneck problem of traditional PEEK materials under extreme working conditions, but also bring new solutions and development opportunities to the field of precision transmission of single-screw machinery. With the continuous growth of market demand and continuous technological innovation, Junhua will continue to lead the industry and provide more customers with high-quality products and services.