PEEK seals | Excellent choice for industrial seals

In the industrial field, the reliability of the sealing ring is crucial, which is directly related to the stability and service life of the equipment. The service life of the sealing ring is affected by many factors, including working environment, operating temperature, pressure, installation quality, etc. Among many materials, PEEK sealing rings stand out with their unique advantages and become a trusted partner in many industrial fields.

01, High temperature resistance, guarding stability under extreme conditions

Facing the severe challenges of high temperature environment, PEEK sealing rings can be used normally at 260℃ for a long time with their excellent high temperature resistance, showing the extraordinary adaptability of PEEK sealing rings. Whether it is the fiery core of a car engine or the extreme temperature fluctuations in the aerospace field, PEEK can maintain stable strength and elasticity, ensuring tight and leak-free seals, allowing equipment to continue to operate stably under extreme conditions.

02, Chemical stability, resistance to corrosion erosion

In corrosive industrial scenarios, the chemical stability of PEEK sealing rings has become a solid line of defense. It can effectively resist the erosion of various chemicals such as acids, alkalis, solvents, slow down the aging process, protect seals from damage, thereby extending the service life of equipment and reducing maintenance costs.

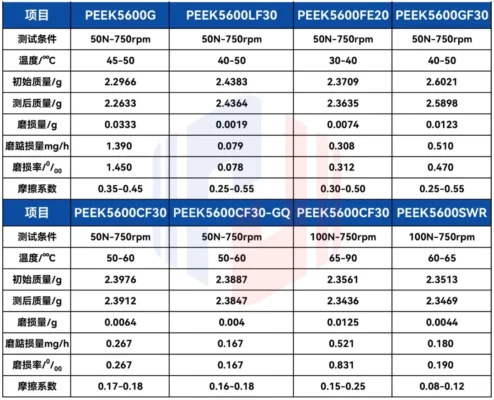

03, Wear-resistant and durable, to meet high-strength challenges

In a high-friction and high-pressure working environment, the PEEK seal ring has demonstrated extraordinary durability with its excellent wear resistance. Its self-lubricating properties reduce friction resistance, reduce wear speed, and ensure long-term stability of sealing performance. Whether it is a high-speed machine or a heavy-loaded equipment, PEEK sealing rings can provide reliable sealing protection.

04, High strength and rigidity, bearing pressure

High strength and rigidity are another highlight of PEEK materials. This allows the PEEK seal to maintain a stable shape under high pressure and provide a reliable sealing effect. In working conditions that require the use of huge pressure, the PEEK seal has become an important force to ensure the stable operation of the equipment with its excellent pressure resistance.

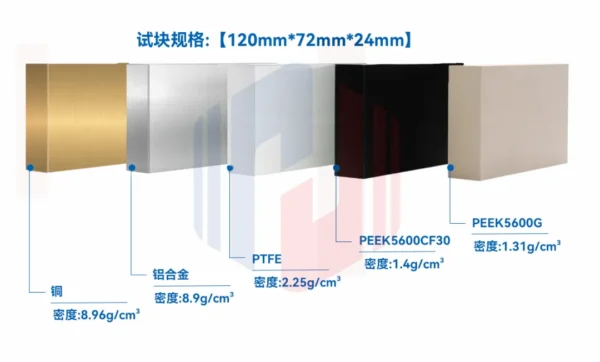

05、Lightweight design leads the future trend

As the concept of lightweight design has become more popular, the lightweight characteristics of PEEK sealing rings have also received widespread attention. Compared with traditional metal sealing materials, PEEK sealing rings are lighter, which helps to reduce the overall weight of equipment and improve energy efficiency. In the fields of automobile, aerospace and other fields that pursue lightweight, PEEK sealing rings are gradually becoming an important force to promote the progress of the industry.

PEEK sealing rings have become the leaders in the field of industrial sealing with their multiple advantages such as high temperature resistance, chemical stability, wear resistance and durability, high strength and rigidity, and lightweight design. It can not only effectively cope with the challenges of various complex working conditions, but also provide long-term and stable sealing guarantee for equipment.

Junhao has been deeply engaged in the field of special polymer materials for 18 years, focusing on the research and development and application of cutting-edge materials such as PEEK and PI, and has built a closed-loop ecology of the entire industrial chain from PEEK resin polymerization to diversified profile extrusion, and then to the design, production and sales of finished parts. It specializes in raw material modification, mold design, profile extrusion and parts processing, forming a complete industrial chain system.

In order to further expand the boundaries of market applications, the company has established a number of professional business units. These business units closely rely on the company’s production technology advantages in special polymer materials such as PEEK, constantly explore the innovative application of materials in various industries, and tailor efficient and reliable solutions for partners. We are committed to promoting the deep integration of special polymers with various fields, helping industrial upgrading and transformation, and creating future value together.